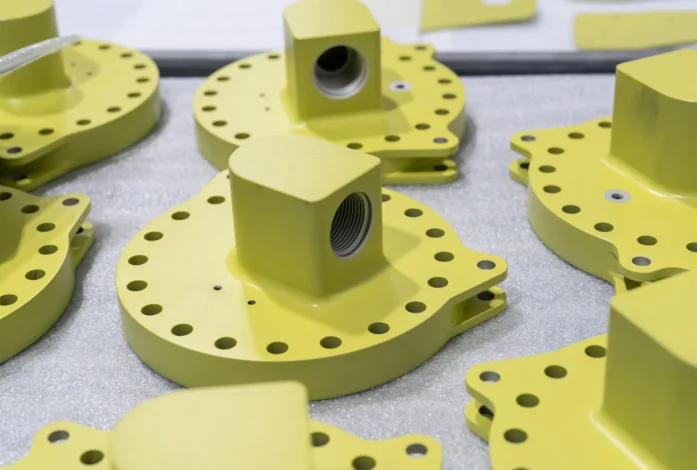

At Shackelford Machine, we know that timely delivery and consistent supply are mission-critical for aerospace, defense, space, and industrial projects. Our advanced, demand-driven inventory system ensures materials and components are available exactly when you need them—supporting both prototype and production runs.

Discuss your project with our experts today.

Our Inventory Capabilities

Demand-Driven Stocking

Inventory levels are continuously adjusted to align with your project schedules and material requirements

On-Time Delivery

Optimized scheduling ensures components and assemblies are ready when needed, minimizing downtime

Diverse Material Support

Titanium, stainless steel, nickel bronze, Inconel, Toughmet, and other specialty alloys

Integrated With Production

Inventory management works seamlessly with CNC milling, turning, mill-turn, engineering, and assembly operations

Prototype & Production Ready

Supports both low-volume prototypes and high-volume production runs with consistent precision

Frequently Asked Questions

How do you manage inventory for different projects?

We use a demand-driven system that aligns with your project schedule, ensuring all parts and materials are available exactly when you need them.

Can you handle large or small volume requirements?

Yes. Our inventory management supports low-volume prototypes as well as high-volume production runs, maintaining consistent quality and accuracy.

Do you maintain specialized materials in stock?

Absolutely. We keep inventory for titanium, stainless steel, nickel bronze, Inconel, Toughmet, and other high-performance alloys.

How does your inventory system improve delivery times?

By coordinating inventory with production schedules and adjusting stock based on demand, we minimize delays and ensure on-time delivery, even for complex assemblies.

Can you manage ITAR-restricted or sensitive projects?

Yes. We are ITAR registered and experienced in handling secure, mission-critical materials and assemblies.