At Shackelford Machine, quality is more than a standard—it’s a commitment woven into every part we produce. From precision CNC machining to assemblies and inventory management, our QA processes ensure that every component meets exacting tolerances, certification requirements, and your specifications.

Discuss your project with our experts today.

Our Key Certifications

At Shackelford Machine, quality and compliance aren’t optional—they’re built into every part we produce. Our certifications demonstrate our commitment to precision, safety, and industry-leading standards, giving our customers confidence that every component meets exacting requirements.

- AS9100 Rev D Certified: Ensures aerospace and defense compliance across all processes, from CNC machining to assemblies and inspections.

- ISO 9001:2015 Certified: Guarantees a robust quality management system focused on continuous improvement and customer satisfaction.

- ITAR Registered: Authorized to handle sensitive defense-related projects securely and in compliance with U.S. government regulations.

Discuss your project with our experts today.

Why Certifications Matter

TRUSTED COMPLIANCE

Certification assures customers that all parts meet strict aerospace and defense standards.

CONSISTENT QUALITY

Standardized processes and audits prevent errors and maintain repeatable precision.

FULL-SERVICE ASSURANCE

From engineering and machining to assembly and inventory, every stage is monitored under certified systems.

Our Quality Focus

We combine advanced technology, rigorous processes, and experienced personnel to deliver exceptional results:

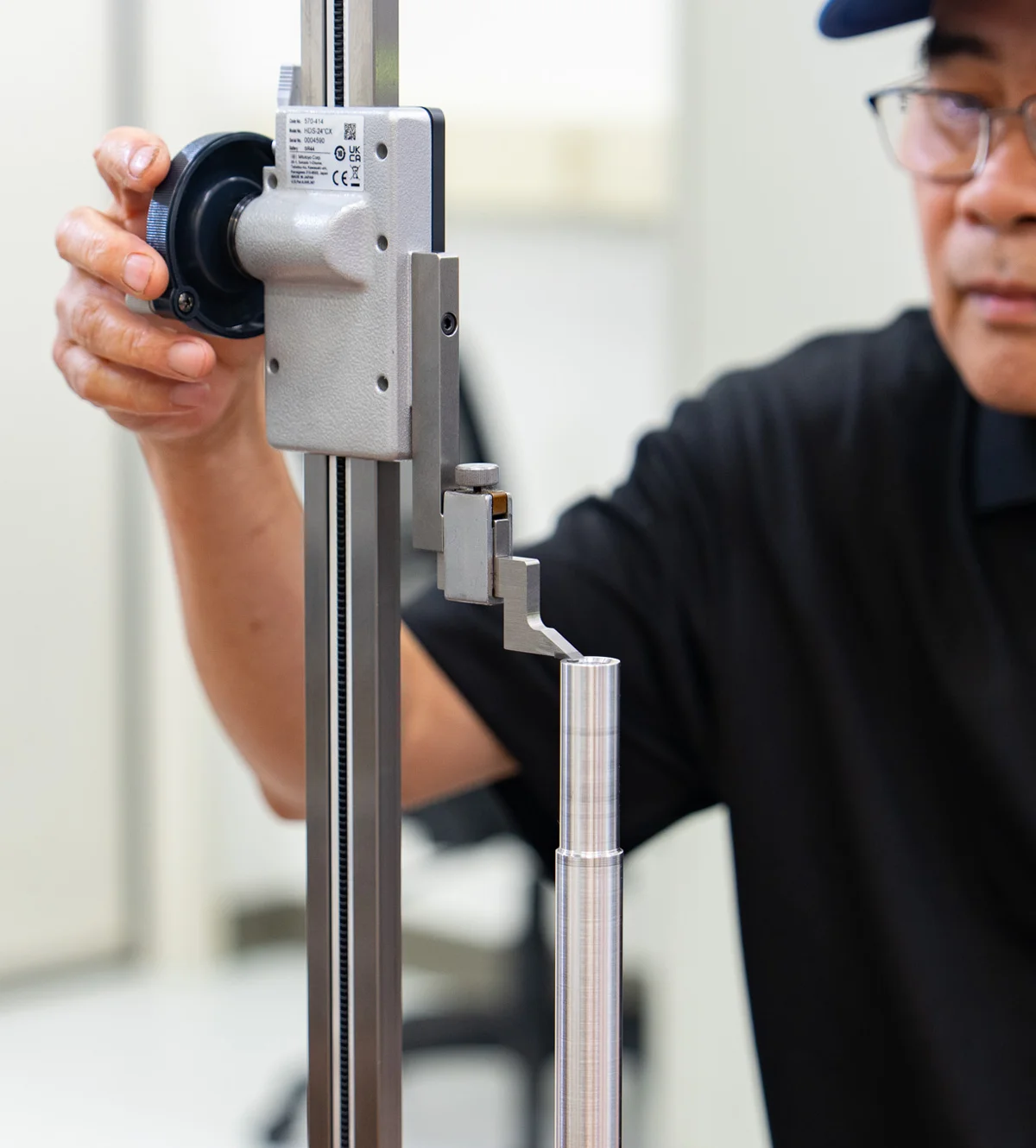

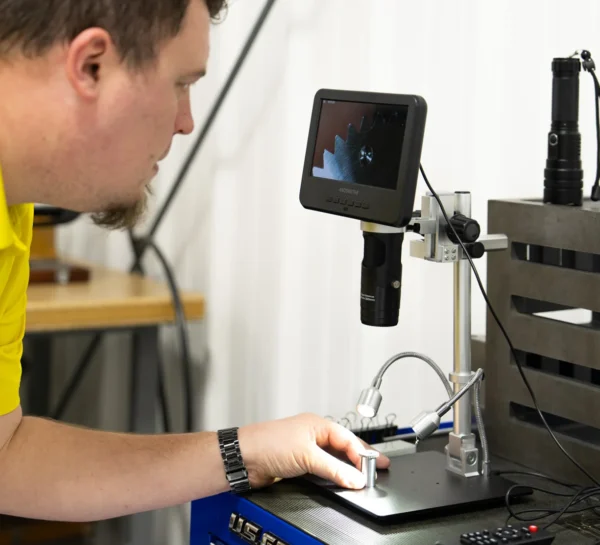

Inspection: In-process and final inspections using CMMs and advanced metrology tools verify every dimension.

- First Article Inspection (FAI): Early verification ensures repeatable accuracy for production and prototype parts.

- Continuous Improvement: Ongoing audits, process reviews, and employee training refine operations and reduce defects.

- Employee Accountability: Every team member is empowered to uphold quality at every stage.

- Client Satisfaction: Quality objectives are aligned with your project requirements to exceed expectations.

Frequently Asked Questions

How do you maintain quality across complex projects?

Quality checks are embedded throughout engineering, machining, assembly, and inventory processes, ensuring every component meets specifications and certifications.

How do you maintain quality across complex projects?

Yes. We are AS9100 Rev D and ISO 9001:2015 certified, and ITAR registered—meeting the strictest regulatory requirements.

Can you provide documentation for quality assurance?

Absolutely. We supply inspection reports, certifications, and First Article Inspection (FAI) documentation for every project.

Can you manage the entire project from design to delivery while ensuring quality?

Yes. We provide turnkey solutions—engineering, machining, assembly, and inventory management—while maintaining strict quality control.

How do you ensure continuous improvement?

Through regular audits, employee training, process reviews, and feedback loops, we refine our manufacturing and inspection processes continuously.