At Shackelford Machine, engineering isn’t just a department—it’s the backbone of every precision CNC machining and assembly project we deliver. From titanium and Inconel components to complex assemblies, our engineers ensure your parts meet the highest standards of quality, reliability, and performance, with faster turnaround than typical aerospace suppliers. Serving clients across the U.S. and internationally, Shackelford Machine is your trusted partner for mission-critical aerospace, defense, and space projects.

Discuss your project with our experts today.

Our Engineering Capabilities

Design for Manufacturability (DFM) Support

Our engineers collaborate early in your project to optimize designs for CNC machining, reducing cost, risk, and lead times. We specialize in hard metals like titanium, stainless steel, Inconel, and Toughmet, as well as assemblies that integrate seamlessly into production.

Process Planning & Lights-Out Machining

From multi-axis CNC machining centers to robotic lights-out systems, we coordinate advanced workflows to achieve exact tolerances. Lights-out operations allow overnight, unmanned production of multiple part numbers, delivering faster results without compromising precision.

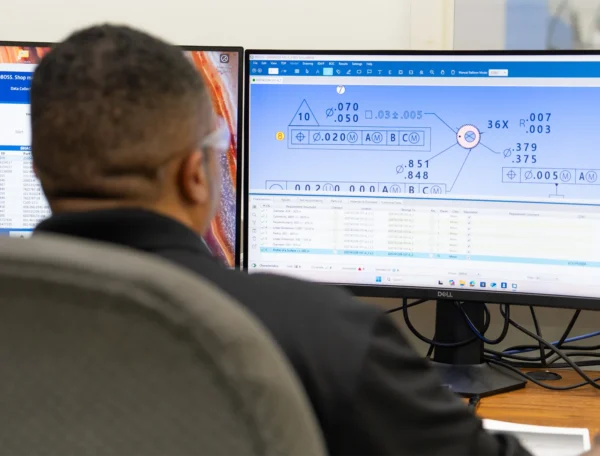

FAI & Quality Verification

Our team oversees First Article Inspections (FAI) with portable and model-based CMMs, ensuring compliance with AS9100 Rev D, ISO 9001:2015, and ITAR standards. Dual QA departments focus on both production consistency and complex, rapid-turn parts.

Reverse Engineering & Prototyping

We can recreate components from physical parts or limited documentation to accelerate prototypes, replacement parts, or redesigns—keeping your projects on schedule.

Tolerance Analysis & Optimization

Complex aerospace and defense parts demand expert tolerance assessment. Our engineers ensure repeatable accuracy across production runs, minimizing scrap and rework.

Industries We Serve

- Aerospace Machining: From commercial jets to private aircraft, we produce mission-critical components that meet the strictest tolerances and certification requirements.

- Defense & Military: Our ITAR-registered processes ensure sensitive projects are handled securely, including fighter jets, drones, and military systems.

- Space Programs: We provide innovative machining solutions for satellites, rocket engines, rovers, and other space components, using materials that withstand extreme environments.

- Industrial & Aftermarket: We support industrial and aftermarket applications requiring precision, repeatable results, including robotics and advanced engineering components.

Frequently Asked Questions

Can your engineers assist with design optimization for complex parts?

Yes. We provide DFM reviews, tolerance analysis, and process planning to ensure your designs are optimized for precision CNC machining.

Are your engineering services included in the quoting process?

Absolutely. Our team collaborates with you from the start to provide accurate feasibility, cost, and lead time assessments.

Can you handle aerospace and defense certification requirements?

Yes. Our engineering team ensures compliance with AS9100 Rev D, ISO 9001:2015, and ITAR regulations at every step.

Do you provide reverse engineering services?

Yes. We can recreate components from physical parts or limited documentation to support prototyping, replacement parts, or redesigns.

Can you handle hard metal parts and complex assemblies?

Yes. We specialize in titanium, stainless steel, Inconel, Toughmet, and nickel bronze, and integrate engineering with assembly processes to deliver fully compliant, mission-critical components.