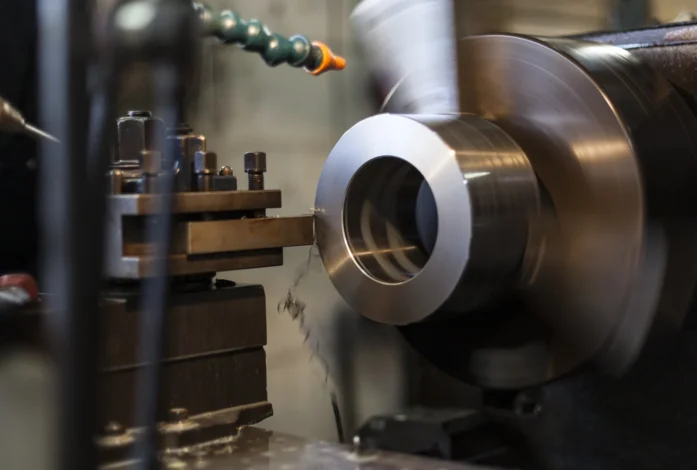

TRUSTED MACHINING BUILT ON DECADES OF EXPERTISE

Founded by master machinist Carl J. Shackelford in 1967, Shackelford Machine began in a small backyard shop with a simple mission: deliver precision machining with integrity, craftsmanship, and a customer-first mindset.

Today, our 60,000 sq. ft. state-of-the-art facility in Clearwater, Kansas combines advanced multi-axis CNC machining, turning, and assembly capabilities with a skilled workforce averaging 12+ years of experience, delivering aerospace, defense, and industrial components that meet the strictest tolerances and certifications. We have five additional acres of land for future expansion, and look forward to continued growth.